Tianjin Ironstar industry co,.Ltd

Tianjin Ironstar industry co., ltd is one professional roll forming

machine manufacturer with ten years of working experience, and 40

workers provide service for you.

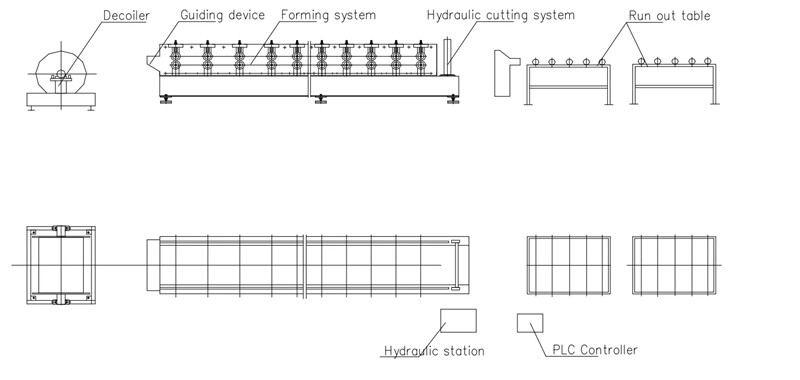

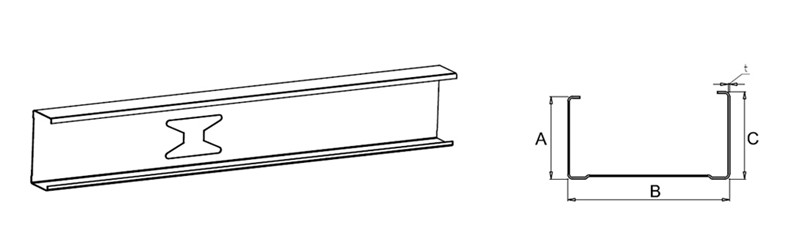

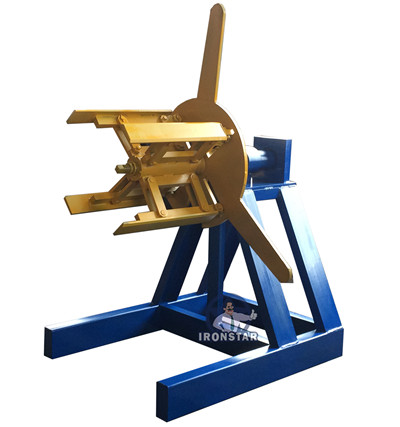

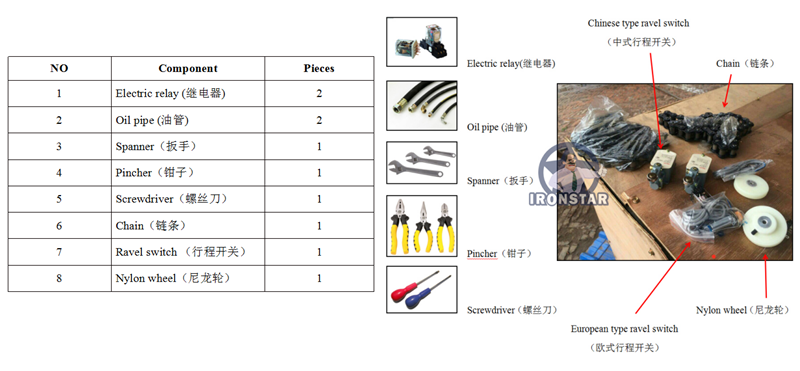

Products mainly include:Trapezoidal steel roof/wall panel machine,

Glazed tile roofing roll forming machines, U channel roll forming

machine, Angle bead roll forming machine, Omega profile roll

forming machine, T bar roll forming machine,

Shutter slat door roll forming machine, Door frame roll forming

machine, C&Z shape interchangeable machine, Cap ridge roll

forming machine, gutter roll forming machine, Cutting, bending,

slitting, and curving machine, Floor deck roll forming machine and

other customized machines, etc.

Creating value for customers and providing customers with the best

quality, the most sincere service, is IronStar's belief and

foundation. We look forward to knowing more friends and creating

more excellent value!